Since 1963, Kimpton have been delivering exceptional M&E Services and HVAC Service and Maintenance across Liverpool, Wirral, North Wales, the North West and UK wide.

With 60 years of experience, our range of projects is wide reaching and varied. Here is a selection of some of our work.

Client: ACC Arena Location: Liverpool Waterfront Project: LED Lighting upgrades Project Manager: Greg Percival LED Lighting upgrades for M&S Bank Arena

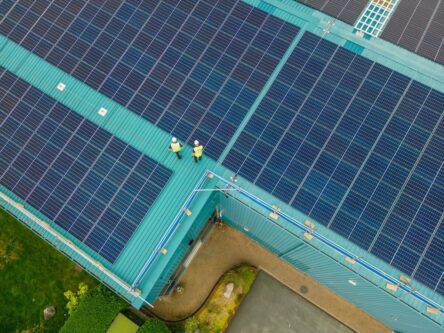

Client: Hitex Location: Ellesmere Port Project: Solar PV Project Manager: Graham Woodward Project Value: £320k Background Hitex Traffic Safety based in Ellesmere

Client: Biograd Location: Liverpool Science Park Project: Laboratory fit-out Project Managers: Scott Bennett and Phil Bowers Background Biograd in Liverpool has

As a business, we are on a mission to reduce the carbon impact of the heating, lighting and electrical systems of our customers in the North West and UK wide.

Our in house team are able to provide a single source solution to deliver any M&E project from design and estimation, through complete installation and commissioning to the ongoing planned and preventative maintenance.

With our ‘right first time, every time’ approach, we’re working incredibly hard to be your lifetime M&E partner.

Innovation has always been at the forefront of our thinking and having installed some of the UK’s first heat pumps for Walkers Crisps and Golden Wonder in the 1970’s, we continue to innovate in renewable energy services, decarbonisation and improving efficiencies.

Our commercial office fit out team deliver office and laboratory fit out projects for clients ranging from property developers and universities to central government departments and the UK’s largest multinational manufacturers.

The business has grown and diversified considerably throughout our history but the focus on service, quality and competitive pricing remains constant.

Across all of our divisions, we work to the highest industry standards, which include accreditations such as Cyber Essentials Plus, Constructionline, Safecontractor, Gas Safe, FGAS, ISO 9001, ISO 14001 and ISO 45001. You can read more about our standards here.

Read the latest news from Kimpton

We have been passionate advocates for sustainable business since 1963, delivering social value to the communities in which we work.

If you would like to discuss any of our services, please call 0151 343 1963 or complete the form below and we will be in touch shortly.