The work is beginning in the Kingsway Tunnel on the £3m project to replace the gravity and pumped drainage pipework. The scale of the project is made clear when you look at the sheer scale of the tunnel system. There are two 9.6m diameter bores and a tunnel length of 2.5km. It’s the second-longest road tunnel in the UK, behind its sister, the 3.2km Queensway tunnel.

The scale becomes even more apparent when you consider that what most people see driving through the tunnel is the space above the road level. The space below, where our work takes place in the invert level.

The image below shows one of the key challenges to the project. The plate in the roof here is one of our access panels, from the roadway above. It’s only 0.7m wide and 6m long. Everything for the job has to pass through these access panels.

The following images show part of the stairwell within the tunnel network. It emphasises the scale again. It’s a 10 storey climb from the bottom to the Seacombe promenade ventilation building at the top. The process for the replacement here is seriously complicated. In order to replace one of the risers, we have to first scaffold the full height of the 40m shaft and then remodel one of the existing pipes into a common riser serving both pumped drainage circuits.

With this in place, we can strip out the old riser, install the new one in its place, before repeating the process to replace the second pipe.

Access to this is via two newly constructed smaller tunnels, being hand-dug, into the bottom of this shaft to allow the new pipework to be connected to the sump from below.

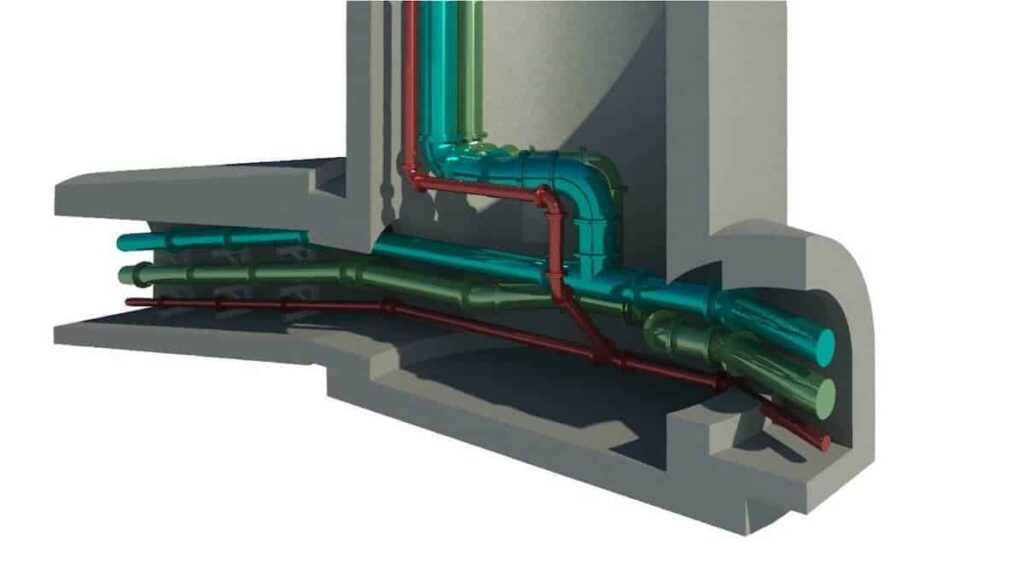

Again, the scale is huge. There are three full-height vertical pipes as you can see from this schematic. The red fire main pipe, as part of the fire protection system and then the two main pumped risers that are 450mm and 350mm diameter respectively. The power of the pumps becomes apparent too when you realise that at any one time, there will be around 6.5 tonnes of water in the pipe that needs to be lifted the 40m to be discharged.

We will have some more images and details about the project as construction work begins over the next few weeks.

If you would like to discuss any of our services, please call 0151 343 1963 or complete the form below and we will be in touch shortly.