Our client for this acoustic barriers project operates a large Bitumen production plant in the UK. Prior to our installation, the machinery was contained within skids, but offered no noise shielding. Increasingly machine noise reduction within production environments is something the Kimpton Acoustic Team are addressing under The Control of Noise at Work Regulations 2005 (Noise Regulations 2005) which require employers to prevent or reduce risks to health and safety of their employees, from exposure to noise at work.

We’ve written a detailed piece here about machine noise reduction.

This project brought a new challenge for us in the design of the acoustic barriers. They needed to be removable for access to the workings of the machinery for servicing, whilst the same time allowing exit for ducted exhaust gases and airflow for cooling, during operation.

With all of these potential issues, noise containment becomes more or a problem and they needed to be able to reduce reflective noise from the machinery used in the production process and shield workers within the plant from potentially unsafe noise levels.

It’s a potentially challenging problem, but one that was overcome with a well planned and executed design solution.

You can see below with the finished installation that the new acoustic barriers are in place and working well. Noise is being reduced around the plant and reflective noise is less of a problem.

We were delighted with this project. It’s another success in our efforts to create safer, quieter industrial work environments.

Bitumen has been used in the UK construction industry, since it was first used as a pavement material in the early to mid 1800’s. Since those early days, its uses have been extended to the roofing industry in many forms and for sealing and insulating applications elsewhere.

In the UK market, bitumen is predominantly produced through fractional distillation of crude oil. This is known as Refined Bitumen. In other markets, similar to tar, Crude Bitumen can be found naturally occurring within areas such as the ill named La Brea Tar Pits in LA or various Oil Sands found in the likes of Alberta, Canada.

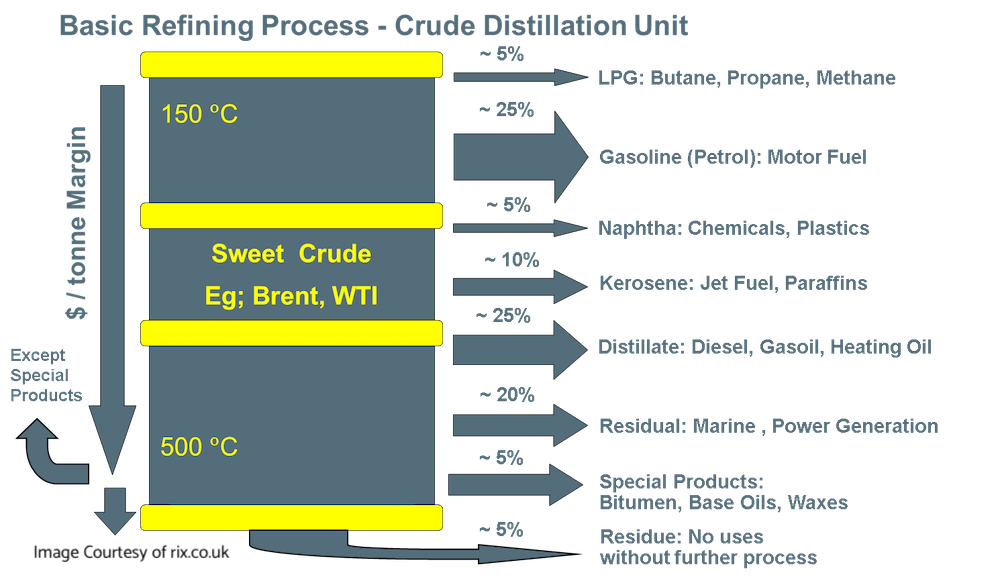

Within the fractional distillation process, lighter fuels such as LPG and Petrol are removed at lower temperatures, leaving the heavier Bitumen to make up around 3-4% of the final product. During this process, it needs to be brought up to around 300 degrees Centigrade or more to separate the Bitumen product. The final Bitumen product as we know it is produced after one further distillation process within a vacuum distillation column.

You can see the full refining process in this diagram.

Bitumen is surprisingly one of the more environmentally friendly bi products of Petrol and Gas production. Not because it isn’t full of nasty carbon material, but by the fact that it isn’t burnt and therefore doesn’t produce any CO2 emissions. It’s also readily recyclable. Worldwide, as much as 70% of Bitumen is recycled.

Unless it is kept at a temperature above 150 degrees Centigrade it forms into a solid wax like substance that is completely waterproof. It’s this property that has made it so useful as a hard wearing sealant.

If you would like to discuss any of our services, please call 0151 343 1963 or complete the form below and we will be in touch shortly.