Client: Hitex

Location: Ellesmere Port

Project: Solar PV

Project Manager: Graham Woodward

Project Value: £320k

Hitex Traffic Safety based in Ellesmere Port, manufacture and install high-performance reflective road markings, anti-skid/high friction surfacing and permanent road repair products.

The group is made up of three interlinked companies L&R Roadlines, Hitex Traffic Safety and Somerford Equipment, specialising in the installation and development of road markings, road safety surfacing and road repair materials along with the manufacture of specialist road marking vehicles and equipment. They are located in three individual factory and workshop units on the same site.

With a significant electricity bill to power the factory units, we worked with Hitex to analyse existing bills and usage patterns to understand where the greatest savings could be made. The decision for a significant installation was made far easier with the scale of the roof space available for Solar PV fitment. Two of the buildings had the most significant power usage, so installation was agreed for those.

The total system comprised of 451 panels on the main factory delivering 180kWp and 110 panels delivering 44kWp on the smaller secondary building. This was designed to deliver a total of 224 kWp of DC power.

The total savings delivered across the two buildings will be over £2.3 million over the 25 year Solar PV panel life.

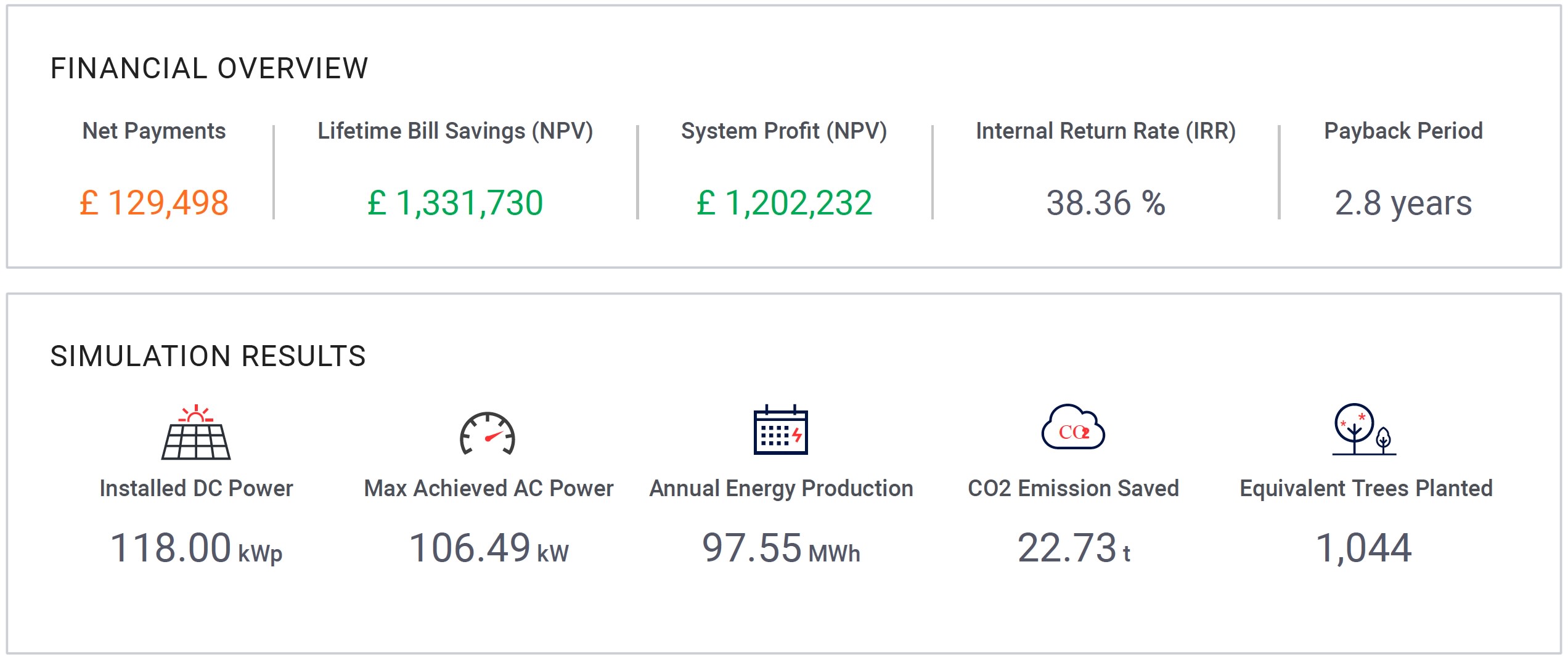

The following figures show an example of the potential energy savings and the profit a system delivers on a smaller 118kWp stem installation.

Firstly, the Financial overview. You can see here that the system is a 118 kWp system and will produce an average of 97.55 MWh annually, saving 22.73 tons of Co2 and delivering a payback of the installation cost in only 2.8 years.

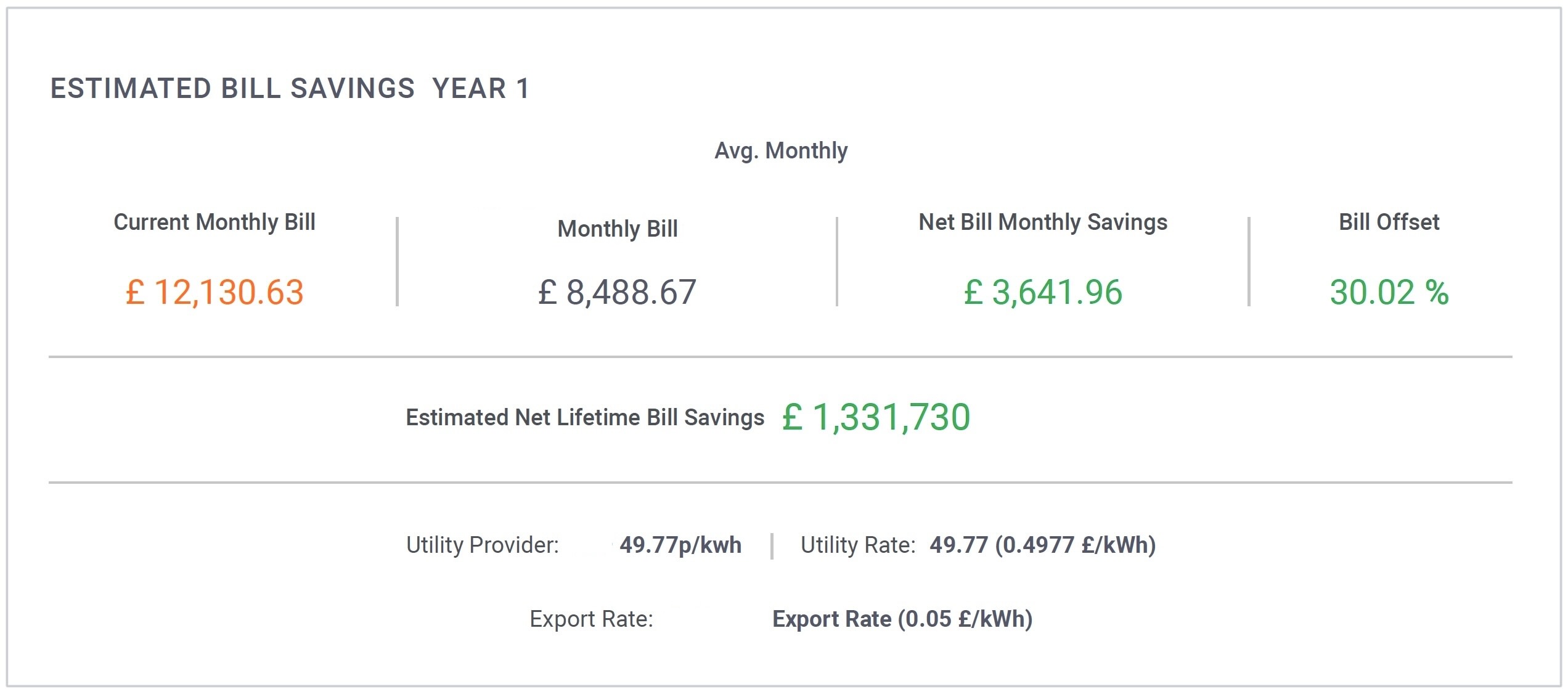

The next image shows the estimated bill savings this can deliver. Bear in mind this is based on an export price of only 5p per kWh, when we are seeing some rates as high as 15p per kWh appearing on the market, which would transform these figures. The current utility rate of 49.77p per kWh is from the customer bills.

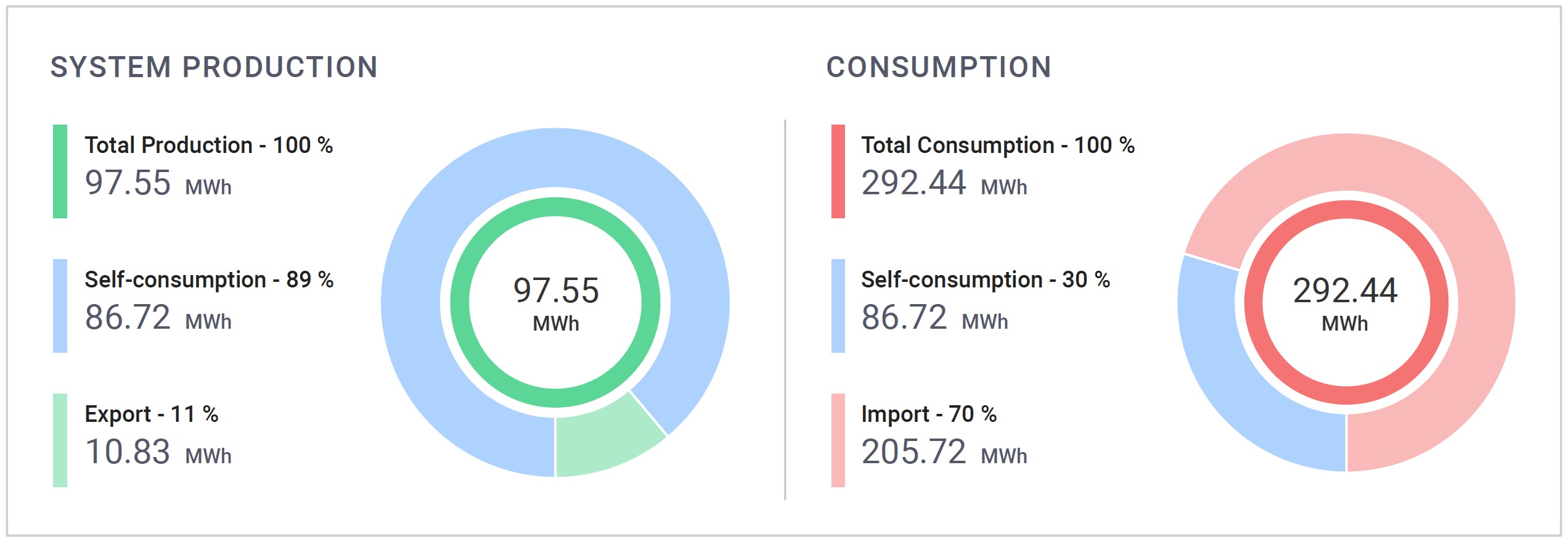

The System production and consumption graph shows that the system as been designed to deliver a target of 30% of self consumption.

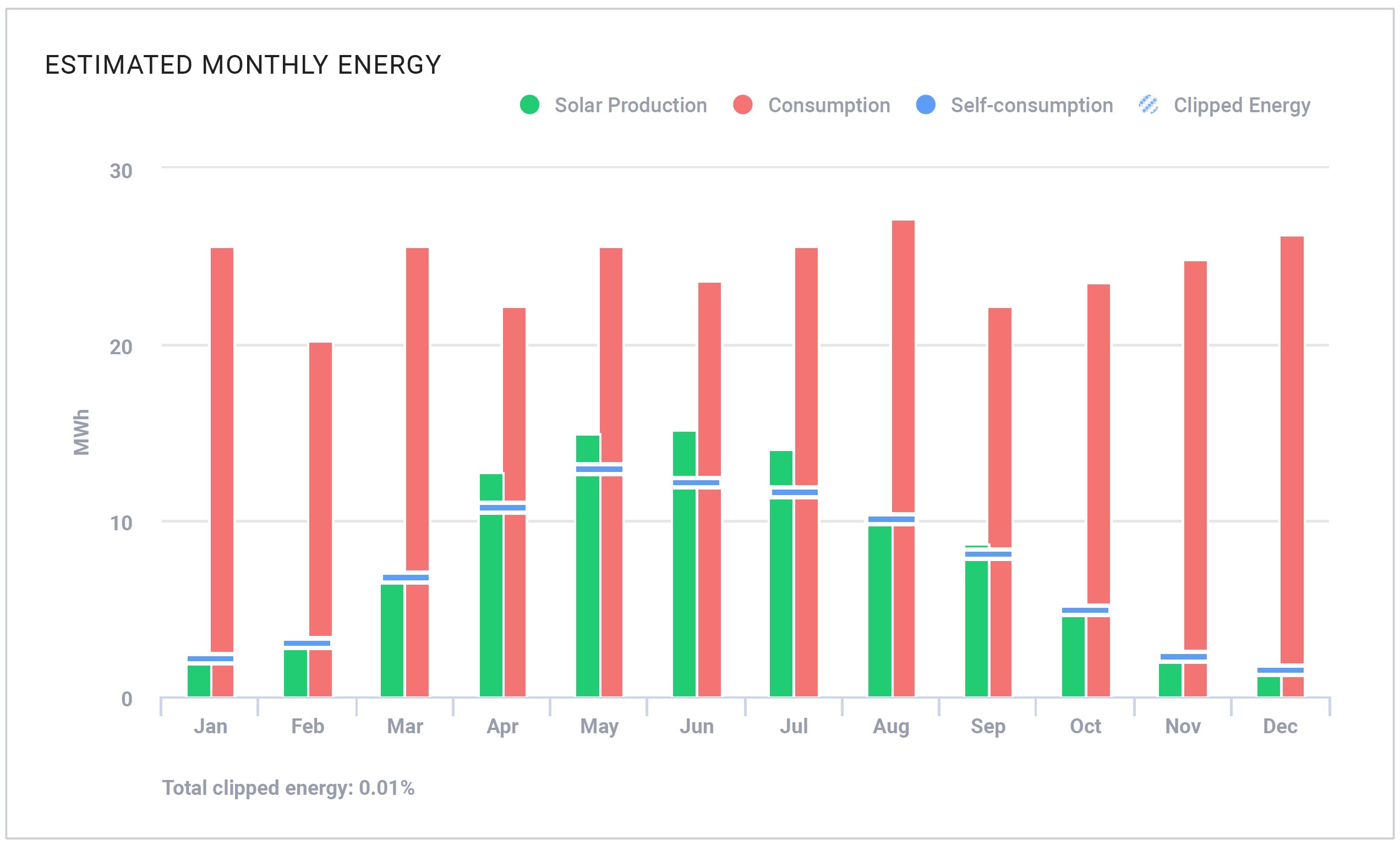

When you look at the estimated monthly usage graphs, you can see where the biggest savings are made. Whilst the Solar PV input makes the biggest impact in the longest and brightest days of May and June, there is still a significant input in the shoulder months and a small input in November, December and January towards the overall usage.

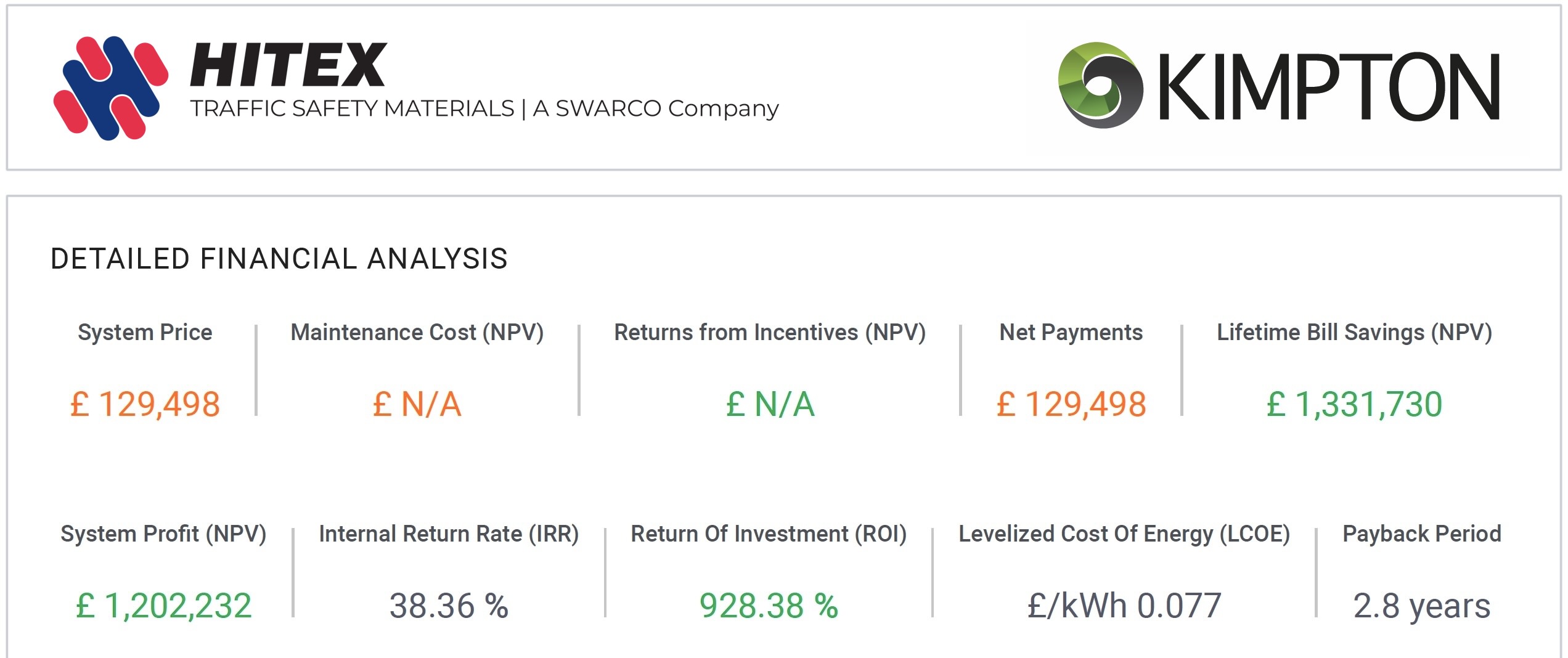

Finally, the detailed financial analysis shows lifetime bills savings of £1.3m and an ROI of 928% over the 25 year expected life. There can be few better investments available anywhere in business. This one also has the advantage of reducing your direct business operational costs AND reducing your carbon impact in a huge way.

The buildings were all scaffolded to allow access and make working at height safe for the team.

We also created a man-safe system for future maintenance teams to be able to work safely at height.

The installation was completed over an eight week period for the two buildings which included the erection of the scaffold, installation and the striking of the scaffold. You can see some of the images of that in progress here.

The finished job was commissioned and handed over to the client and is now fully operational. You can see that below.

The finished job is MCS Certified. This is a requirement for grid export. MCS certifies low-carbon products and installations used to produce electricity and heat from renewable sources.

If you would like to discuss any of our services, please call 0151 343 1963 or complete the form below and we will be in touch shortly.