Client: LJMU Plant room refurbishment

Project: School of Nursing and Allied Health

Value: £750k

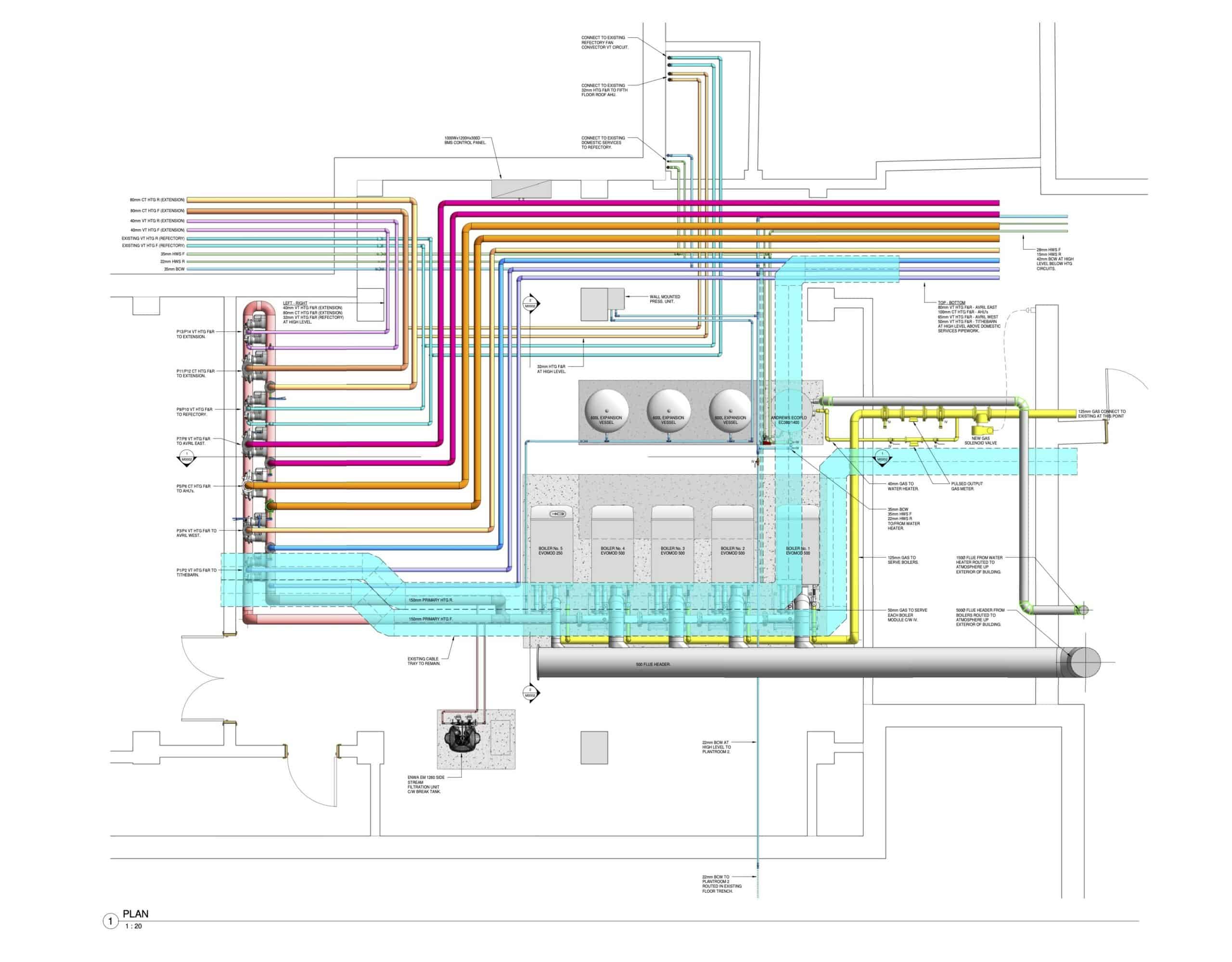

As part of the overall £6.5m project to refurbish the Tithebarn building and develop the new Avril Robarts Library, the Kimpton team carried out a complete refurbishment of the main basement plant room, within the Tithebarn building.

The project brought some of the most significant challenges we have faced in any plant room refurbishment project.

The first of these was access. Bearing in mind the size and scale of the project, every element, from boilers, water heaters, pumps and pipes needed to be hoisted down to basement level using specialist lifting gear and then wheeled into place through a double doorway access to the plant room. This entailed a logistics plan to ensure everything was accessible when required and needed to be very tightly designed beforehand.

The second challenge was asbestos on site. What this meant in practice was almost no drilling into walls and ceilings. We had to create a goalpost system to carry much of the pipework through the plant room and to allow it to feed into the main risers. When a fixing was required, this had to be marked by us and completed by the asbestos specialists. Again, it made logistics very challenging.

The third challenge was the space itself. Whilst the plant room, once you were in there, was a great size, the routes in and out for pipework entailed a complicated network of pipes. This is normally easy enough, but as we were dealing with a 5″ gas main and a range of LPHW pipes from 4″ down to 2″, it meant everything had to be trial fitted, tacked and tested before being dismantled again to be fully welded up.

Within the basement plant room, there are nine individual Hamworthy Wessex Modumax Mk3 250kW boilers, linked to three expansion vessels, delivering a total 2.25mW of heating power. Four of these are double stacked, with one single. There are seven individual pumps sets and circuits, feeding LPHW and domestic hot water throughout the building.

Prior to our work starting on site, we had been into the existing plant room and drained, purged and made safe all of the supplies, so that the demolition team who were tasked with clearing the site and had asbestos specialists within the team, could complete their work. The previous boiler system was made up of four sectional Hamworthy boilers, two of which had failed.

The incoming 5″ gas main was extended by over 20m for the new plant room layout. This allows plenty of space for expansion in the future.

The expansion vessels that were fitted to the system were located on a newly extended plinth, where the old boilers had been sited.

As per the standard specification for all LJMU plant rooms, a new EMWA filtration unit was added. This is a very high spec system that will help ensure the longevity of the system.

The final aspect is a gas-fired Andrews Water Heater to supply the hot water to the site. This is all supported by a central control system for easy management and operation. This is a large scale plant room purpose-designed for maximum efficiency overall. It allows us good access for future Planned Preventative Maintenance and despite the slightly limited access, there is plenty of space for expansion in the future.

If you would like to discuss any of our services, please call 0151 343 1963 or complete the form below and we will be in touch shortly.