Daresbury Laboratory opened in 1962 in Halton, Cheshire, close to Warrington. It’s a world leader in scientific research in areas as diverse as nuclear physics and supercomputing.

There are over 300 staff, who work across 20+ plus individual buildings with purpose-built lab and office spaces, designed specifically with high-level research in mind.

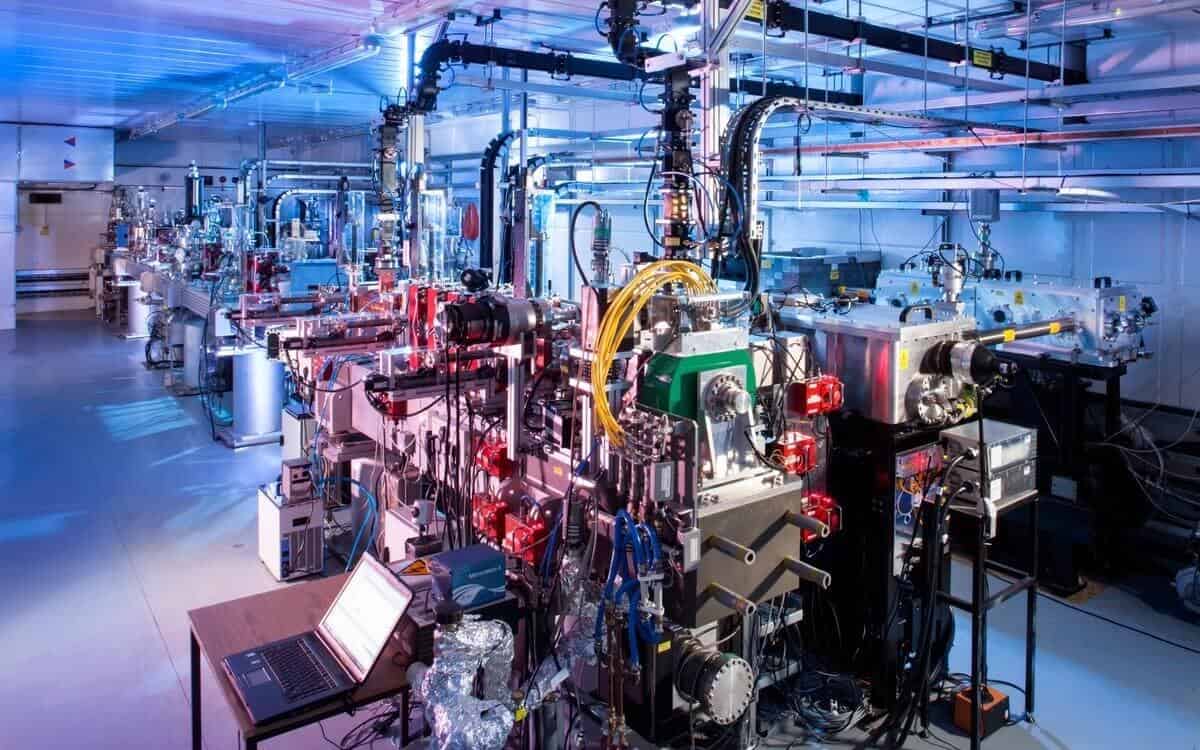

The Kimpton PPM team maintain over 450 individual pieces of plant, across 23 individual buildings. At the smaller end, there are (a lot of) individual cassette units within office spaces and at the top end, huge Air Handling Units (AHU’s) designed to move air through the lab facilities, blast chillers, conventional heating and hot water boilers and everything in between.

The value of the PPM contract is around £30k per annum plus an anticipated £250k of HVAC upgrades expected to be carried out every year over the four-year contract.

Every individual item of plant is logged and tagged within our system and maintenance work planned and completed in turn. If there ever is an issue with plant, the client can notify us and we will know exactly which item they are referring to and carry the spares to be able to get it up and running again as soon as possible. With every item, there’s a planned programme for the work, with some only requiring annual maintenance and other more critical items, requiring planned visits four times per year.

One advantage of the PPM programme is that we can carry out routine maintenance on plant when it is at its period of lowest demand. Even with British summers, heating boilers are used less in the summer and maintenance can be completed with little risk to staff welfare. Conversely, much of the comfort cooling is under less pressure in the winter and we can plan in the service programme to fit.

The key challenge is with there being over 450 individual assets of varying ages and condition. There is a rolling replacement and upgrade plan in place, so new, more efficient plant is installed as the old plant reaches the end of its economic life. The flexibility and depth of knowledge across the Maintenance Department at Kimpton means we have service engineers able to work on plant such as commercial boilers to industrial blast chillers in-house.

The Kimpton asset management system and the PPM programme itself does work to keep breakdowns to an absolute minimum, but the breadth of different equipment and the sheer scale of the operation at Daresbury do present challenges for the management team and the individual engineers.

With nearly 60 years in the industry – forming only one year after Daresbury was first built – it’s a challenge the Kimpton team has been designed to meet perfectly.

If you would like to discuss any of our services, please call 0151 343 1963 or complete the form below and we will be in touch shortly.